Career potential H2

Hydrogen engines can facilitate climate-neutral mobility or form part of a secure energy supply. And current FVV research projects are highlighting further potential.

Ideal characteristics // Many thermodynamicists believe that hydrogen is the ideal energy carrier. Its gravimetric calorific value is around three times higher than that of petrol. Hydrogen is readily combustible and does not contain any carbon, which can form carbon dioxide or lead to combustion residues such as particles. And above all, when used as a storage medium for solar and wind power, hydrogen offers the option of decoupling energy generation and demand in terms of both geographical location and time. Prime movers that are operated directly with hydrogen can use the green electricity harvested and chemically stored elsewhere, thus facilitating climate-neutral mobility or forming part of a secure energy supply. In particular, heavy goods vehicles deployed in longdistance transport or mobile machinery used around the clock can be made climate-neutral quickly with hydrogen engines. And although this model student is already celebrating its first successes, the hydrogen engine still needs to excel in a few more tests to reach the zenith of its career.

FVV’s pre-competitive collective research is making a contribution here, as evidenced by the ›Acoustics of Hydrogen Piston Engines‹ project to name but one example. This project is addressing an area where the hydrogen engine actually has a major advantage: the fact that its conversion process during combustion is very rapid. The flame front moves through the cylinder several times faster than is the case with fuels containing carbon. Although this is highly efficient, the resulting high pressure gradients pose a challenge for the acoustics experts.

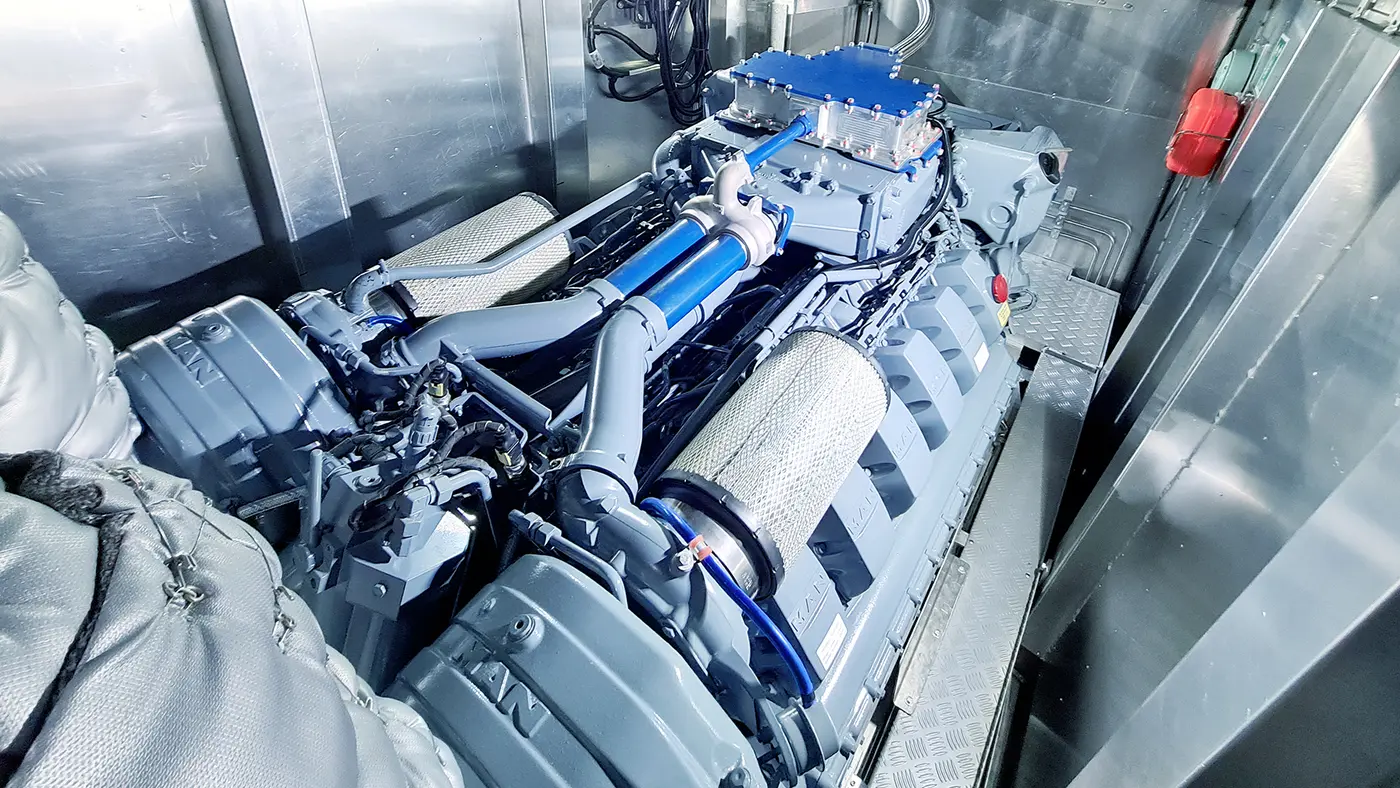

To assess the acoustic properties of an engine from an early development stage, sophisticated simulation models have already been created in previous FVV projects. Dr. Stefan Heuer, who is responsible for acoustics and vibrations in the development team at MAN Truck & Bus, completed a doctorate on the subject around 25 years ago as part of an FVV project. In his role as project manager, he is now coordinating the new project, which began in mid-2022 and is expanding the existing simulation models to include hydrogen combustion. »We need to better understand how cause and effect are linked,« explains Heuer. »We need to have a precise understanding of the variables for specific acoustic phenomena in order to optimise the noise emissions.«

One peculiarity in this project is the fact that the data used by the RTD performer at RWTH Aachen University isn’t actually collected in the project itself. Instead, the researchers are drawing on test bench data that is being generated in five other FVV hydrogen projects. »Otherwise, it simply wouldn’t be possible to achieve valid results in a project lasting just twelve months,« says Heuer. He is confident that networked, cross-institute research in FVV can achieve added value, especially with respect to the study of new combustion processes. »This is how we can reach our goal with a relatively small amount of money and in a shorter period of time.«

Nevertheless, hydrogen engines need to do more than simply demonstrate acceptable acoustic properties – they also need to comply with all current and future emissions limits. While this is something that is relatively straightforward for pollutants containing carbon, nitrogen oxides present more of a challenge. The high combustion rates and the high peak temperatures in particular cause oxygen not only to combine with the hydrogen, but – depending on the air-fuel ratio – to also bond with the nitrogen present in the ambient intake air. »Nothing comes from nothing,« as the saying goes, and this prompted the idea of substituting the ambient air with a carrier gas that does not take part in the combustion process. Pure oxygen and hydrogen are then supplied to the engine, while the carrier gas is circulated – which is why it is referred to as a ›closed-cycle engine‹.

This is how a closed-cycle engine works

In an FVV project that was completed at the end of 2021, researchers at Otto von Guericke University Magdeburg investigated the ›potential of a self-igniting closed-cycle hydrogen engine‹. One key question that needed to be answered was whether there is a substance that would be suitable as a carrier gas. With the aid of a simulation model calibrated on a real hydrogen engine, three potential gases were examined: argon, helium and neon. Once all the characteristics had been combined, it soon became clear to the researchers that argon best met the requirements of the thermodynamicists. What’s more, the noble gas is also completely safe from an environmental perspective: it already accounts for almost one per cent of the atmosphere and is the third most abundant element in the air that we breathe.

Project coordinator Dr. Markus Wenig, a department head at the large engine developer WinGD, points out the following: »In addition, argon is the most cost-effective solution, as it has a positive impact on overall efficiency.« However, the costs of the noble gas do need to be considered. Even though it is not involved in the combustion process, it has to be replaced after around 60 days of operation. This is because it gradually becomes contaminated with carbon dioxide that arises from the combustion of lubricating oil. Overall, the university’s cost-benefit analyses, which were based on a period of 20 years, revealed a cost advantage of ten per cent for the closed-cycle mode of operation, as it cuts out the need for exhaust gas aftertreatment.

»The closed-cycle principle is less suited to mobile applications,« says Wenig. »Stationary modes of operation, such as applications to stabilise electricity grids, are a more interesting prospect.« He adds that direct coupling with electrolysers is conceivable, as they don’t just generate hydrogen from green electricity, but also produce the pure oxygen as a by-product. The efficiency calculated by the researchers stands at around 53 per cent for an energy recovery system of this nature. »It is certainly worth pursuing the matter further,« says Wenig. »It’s fantastic that – as a small company with fewer than 500 employees – FVV gives us the opportunity to investigate such vital topics.« ||