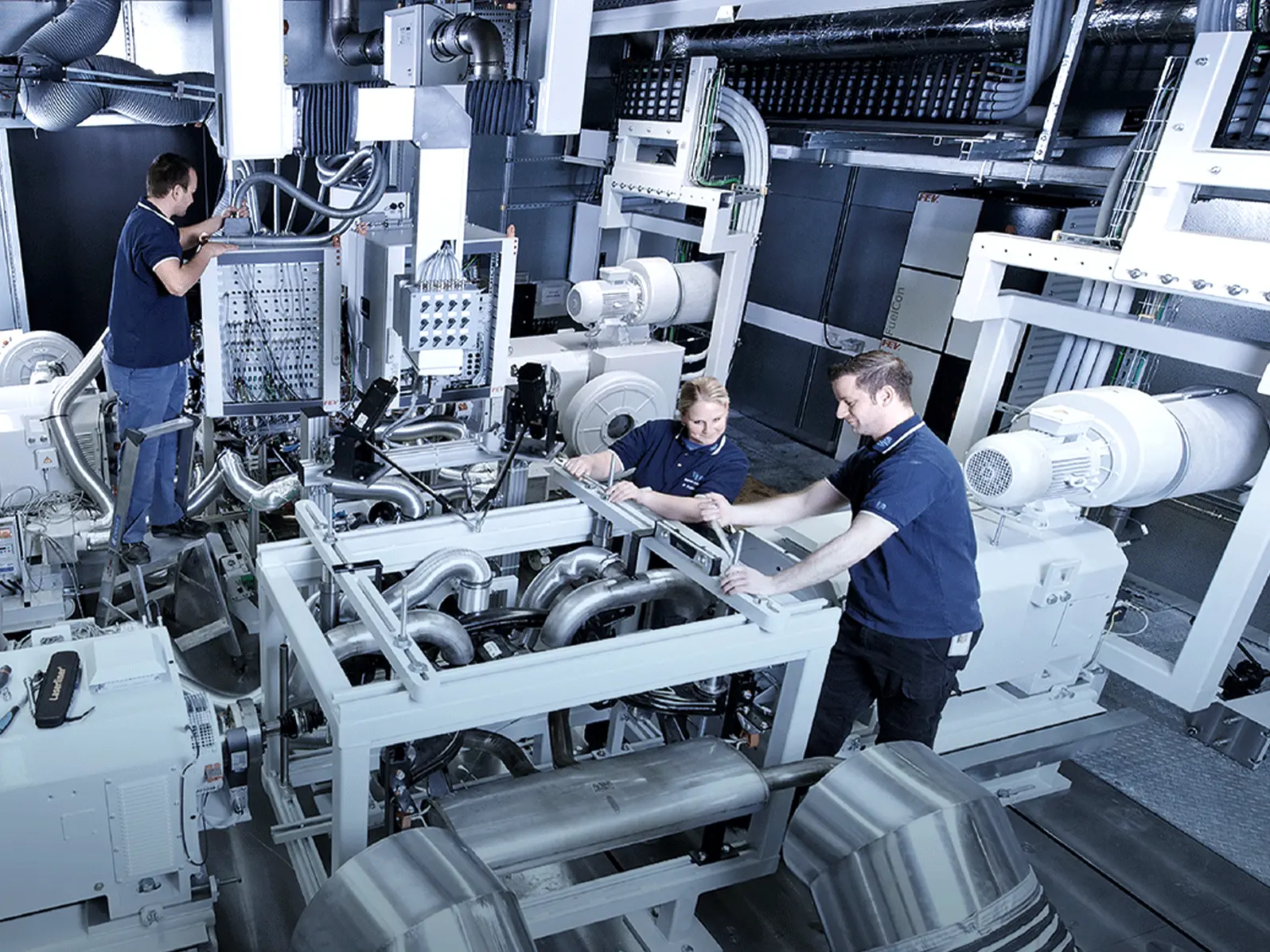

Knowledge and technology transfer

All things energy transition

Designing components safely and efficiently

Peter Gutzmer talking to energie+MITTELSTAND

Hydrogen engines do have a future

Enabling research through research management

Knowledge transfer #07/23

Five voices from our member companies on ›Make it new‹

Climate-neutral and resource-efficient mobility

Prof. Dr. Thomas Koch explains what young engineers should learn today

Industrial Collective Research moving into a new era

FVV Award winners on young researchers in science

Martin Urban works on economic solutions for a climate-neutral energy system.

FVV gives insights into sustainable pathways to climate neutral mobility

FVV publishes annual magazine 2022

Thomas Korn from Keyou has been working on hydrogen engines for many years

Impact on air quality as a benchmark

An interview with Dietmar Goericke

Sustainability is more than just climate protection: Boundary conditions for sustainable mobility

Sustainability as a compass

From gear wheel edges to coil insulation

Facts over feeling

Individuals reach their limits relatively quickly

ICE2025+: the ultimate system efficiency

An interview with Christopher Steinwachs

Names carry traces of the past

Patiently creating space for something new

DME as an alternative fuel for Compression-Ignition Engins

New FVV meta-analysis of LCA Studies on Alternative Powertrain Technologies

Options for climate-neutral mobility in 2050

Developing a generic fuel cell stack

E-Crude-Produktion in Norwegen