The power lies in the system

Martin Urban, who describes himself as an ›engineer with a wallet‹, works on economic solutions for a climate-neutral energy system. For the head of development at Rolls-Royce Power Systems, the focus is not on individual components, but on the system as a whole.

It works!

Sunday evenings were always craft time. Martin Urban’s father, a humanities scholar with craftsman's skills, shared his passion for model aircraft construction with Martin and his siblings. Martin was twelve years old when he built his very first airplane – not from a kit, but from a construction drawing. »There were moments of frustration when everything wasn’t working as it should right away,« Urban recalls today. »But that didn’t stop me from always trying something new.« The first model flew with a small single-cylinder combustion engine. Later, he upgraded to an electric drive and realised that this worked, too; however, the battery didn’t hold up very long. When Urban was asked as a teenager what he wanted to do for a living, he answered: »I want to build airplanes.«

So it’s hardly surprising that Urban went on to study aerospace engineering in Aachen and chose particularly demanding subjects to specialise in: rotary wing aircraft and aircraft propulsion systems. In addition to his main studies, he worked as an intern and student trainee in flight testing at DASA’s Manching site. Urban not only gained technical knowledge here, but also developed his own personal ›energy conservation law‹: »I can put a lot of energy into something if I get at least as much out of it.« And so, despite the part-time job, Urban completed his studies in almost the standard period of study.

If we as engineers develop technical solutions, they must have an economic value for society.

The fact that his path did not immediately lead him to aircraft construction, but to stationary gas turbines, was due to a chain of various circumstances – but most importantly due to the fact that Urban proved himself in a number of very different positions at Siemens, his first employer after graduating. After two years as a test engineer at the Mülheim site, he was allowed to go out into the world and take measurements on customer plants. His first accolade followed in 2000, when Urban was given responsibility for the large 42 People gas turbine test bench in Berlin. At the historic site built in the middle of the Moabit district, Urban supported the electrical company in developing a gas turbine with 43 per cent efficiency – the world’s highest efficiency rating at the time. But the energy world is always changing rapidly, and more and more combined cycle gas and steam power plants were being built. The system efficiency counts for more than the absolute best value for the gas turbine. In order to increase the system efficiency, higher exhaust gas temperatures were necessary – which meant that a new combustion process was required. Urban started developing just such a process with a team in Orlando, Florida in 2003. A few years earlier, Siemens had bought Westinghouse’s non-nuclear power plant business, and now the task was to develop common technical standards.

When Urban assumed responsibility for the product line development of Siemens gas turbines in 2006, work began on the Irsching combined cycle gas and steam power plant, which held the world efficiency record from the time of commissioning until 2016. Accordingly, the CO2 emissions per kilowatt hour were low. However, due to the electricity market structure and the associated rapid changes, the power plant was only able to achieve a few full-load hours. As an ›engineer with a wallet‹, as he describes himself, Urban takes a sober-analytical look at the past and tries to learn from it for the future. »If we as engineers develop technical solutions, they must have an economic value for society.«

After holding a few more positions, in 2014 Urban took over development responsibility for the recently established Siemens business unit ›Distributed Power Generation‹, which focuses on small, distributed power generation plants. At the centre of this kind of plant there is still a gas turbine, with a maximum of 65 megawatts. However, Urban instantly recognised that »Individual components do not count in a business like this. It always comes down to system performance.«

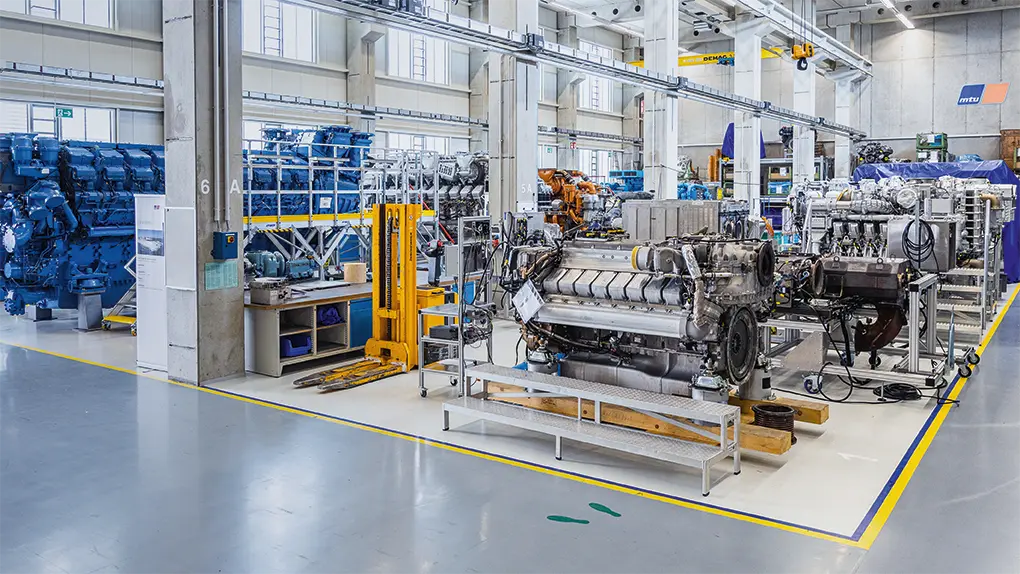

Three years later, Andreas Schell, whose term as CEO of Rolls-Royce Power Systems had just begun, knocked on Urban’s door – and he took over responsibility for system development. »At that time, not everyone had realised the tremendous impact of the pending change. We were able to work ahead and put ourselves in a situation where our customers have a choice today.« The expanded spectrum of the supplier, which still uses the Motoren- und Turbinenunion logo for its products, is illustrated by a ›Validation Center‹, which realistically and vividly reproduces a complete system consisting of the new products. It consists of a battery storage system that stores the solar power generated on the roofs of the factory, a power generation module in which four fuel cells are used, and the complete automation for this micro grid. In addition, combined heat and power plants and diesel gensets are integrated. A module with a hydrogen combustion engine is nearing completion during the visit, and an electrolysis module is to be added later, using technology from the Wismar-based start-up Hoeller, in which Rolls-Royce Power Systems has just acquired a 51 per cent stake.

Urban makes it clear that, as well as being the most important source of revenue at the moment, the combustion engine will continue to play an important role in the future. »It is the very heart of our business. With our engine expertise, we have proven to customers that we are worthy of their trust.«

The power lies in the system – this is also the message Urban brings to the team, where conventional engine developers are increasingly interacting with employees from acquired startups. According to Urban, the different cultures can be successfully bridged through one thing in particular: collaborative working, encouraged in part by the fact that project teams physically move into shared spaces. Besides scientific results, Urban considers the opportunity for exchange as the most valuable advantage created by FVV. »There are so many open questions – for example, which combinations of energy converters and energy sources make sense for which applications. FVV is an important forum where these issues can be discussed in a scientifically substantiated manner.«

As far as model aircraft building is concerned, the issue of the ideal propulsion system also remains open. Martin Urban is regularly making time for crafts again – this time with his 13-year-old godson.

Martin Urban, born in 1971, studied aerospace engineering at RWTH Aachen University.

After graduating, however, he spent 21 years at Siemens – most recently with development responsibility for the distributed power generation business. In 2017, he joined Rolls-Royce Power Systems. Since January 2022, he has been responsible for all aspects of development at the propulsion and energy solutions provider.

Martin Urban volunteers as a member of the board of FVV.